In industry, being accurate and efficient is very important. CNC milling technology is changing the way we create and make products. This process uses machines operated by computers to cut detailed forms from solid materials very precisely. CNC milling is being used in many fields, from making complex parts for aerospace to crafting custom furniture.

As we explore this new method, we will highlight its many benefits compared to traditional ways of making things. The benefits are significant, including improved efficiency and less waste. Come along as we look at how this important technology is being used and what it might do in the future in our changing industries.

Benefits of CNC Milling Compared to Traditional Methods

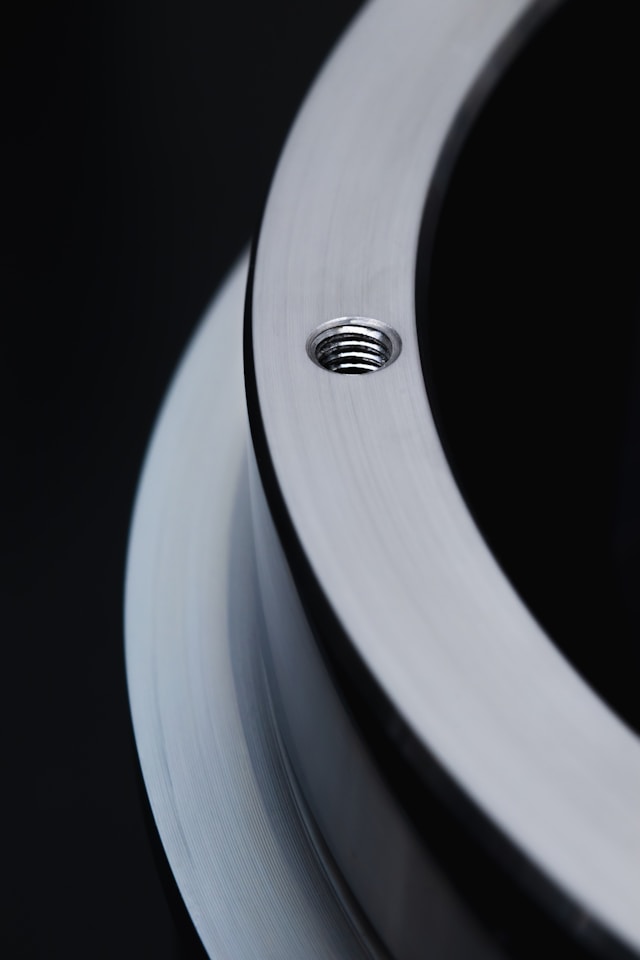

CNC milling technology has several benefits that make it better than standard manufacturing methods. One of the biggest advantages is accuracy. The CNC milling machines use computer-controlled machines to achieve precise measurements that manual machines find hard to match reliably. Speed is also very important. Tasks that used to take hours or even days can now be done much faster. This speed helps businesses react quickly to market needs and shorten delivery times.

CNC cutting is very flexible. It can handle different things like metals, plastics, and composites. CNC machines can easily make both complex parts and simple pieces. Also, automation greatly lowers the chances of human mistakes. Operators can concentrate on managing processes instead of doing repetitive jobs by hand. This change improves quality and increases safety at work by reducing direct touch with heavy machines.

Uses and Fields for CNC Milling

CNC milling technology is used in many businesses, changing how products are made. In flight, accuracy is very important. CNC tools make detailed parts that follow strict safety and performance rules. These parts usually consist of brackets, housings, and rotor blades. The car industry also gains a lot from this technology. Manufacturers use CNC milling to make engine blocks and gearbox cases with precise measurements to improve car performance. Making medical devices depends a lot on CNC cutting. Surgical tools and artificial body parts need to be very accurate, so makers use this technology to make sure they are dependable in important medical situations.

The electronics business uses CNC milling to make circuit boards and cases for devices such as smartphones and computers. This makes sure it works well and looks good. CNC technology is used in many areas, from art sculptures to architecture, allowing for unique designs that old methods couldn’t create. The ability to adapt is really impressive.

The Future of CNC Milling: Progress and Opportunities

The future of CNC cutting technology looks promising and has a lot of possibilities. CNC tools are getting much better and more advanced because of quick improvements in automation and artificial intelligence. These new ideas will help makers make complex designs more accurately and efficiently, reducing waste. CNC cutting is also improving in terms of sustainability. As businesses move towards being more environmentally friendly, companies are using more sustainable materials and methods. Focussing on eco-friendly production fits well with CNC milling because it creates less trash, which reduces the carbon footprint.

As 3D printing becomes more popular, it works alongside standard CNC machining instead of taking its place. Combining these technologies could create mixed manufacturing solutions that take advantage of the benefits of both methods. Think about combining the freedom of 3D printing with the accuracy of CNC machines to create new and exciting products. Education and training are important for building the future. As more skilled pros join the field of advanced machinery, we can expect a rise in creative ideas that will result in innovative applications in different industries. As we look at new developments in manufacturing technology, CNC milling is leading the way. It is changing businesses and opening up many new opportunities through innovation.