Envision a future where industries are revolutionised by accuracy and precision, surpassing our preconceived notions of what is feasible. Leading this drive are extraordinary developments in spectrum laser technology that have the potential to completely revolutionise industrial processes in a variety of industries. As these potent instruments advance, they not only boost output but also open up new avenues for creative applications that were previously constrained by conventional techniques. Prepare to enter a world where innovation and light collide, paving the way for a fascinating future in spectrum laser applications.

Improvements in Accuracy and Precision

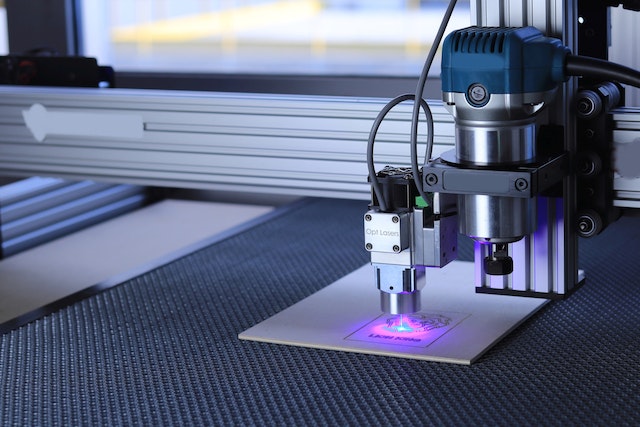

Laser technology has advanced significantly in terms of precision. The most recent spectrum lasers use sophisticated algorithms to improve performance precision. These advancements are revolutionary in many sectors because they enable more detailed designs and finer cutting.

Real-time data analysis is now possible for machines thanks to the integration of artificial intelligence. With this flexibility, changes may be made quickly to ensure peak performance and cut down on waste.

Furthermore, improvements in beam quality have produced focus spots that are sharper. Manufacturers are thereby benefiting from increased productivity and lower material prices.

These developments greatly reduce manufacturing times while simultaneously improving product quality. These advantages are being felt by a variety of industries, including aerospace and healthcare, as applications move more into jobs requiring accuracy. For those working on spectrum laser technology, this is an exciting moment since each advancement opens up new possibilities. You may visit spectrum laster news for more details.

Novel Concepts for Industrial Applications

Across several industries, industrial applications are being redefined by spectrum laser technology. Producers are coming up with innovative strategies to increase output levels and product quality.

The employment of spectrum lasers for precise cutting in the aerospace industry is one noteworthy accomplishment. The whole process may be streamlined by using these lasers to generate complex patterns with little waste of material.

Furthermore, spectrum lasers are being used by the automobile sector to weld components with unmatched precision. Stronger couplings are guaranteed by this technique, which also drastically cuts down on assembly time overall.

Spectrum lasers enable previously unthinkable micro-machining jobs in circuits. They enable producers to create smaller components without compromising dependability or performance.

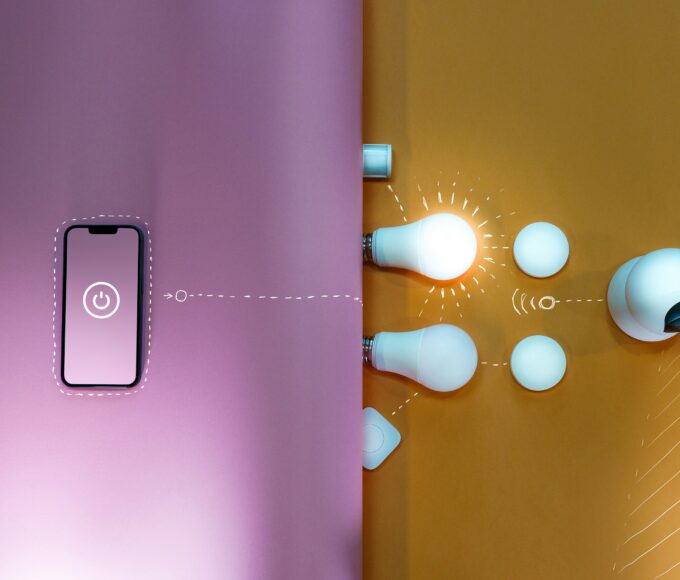

Smarter operations are also made possible by the use of AI into spectrum laser systems. Adaptive modifications during manufacturing are made possible by real-time data processing, which reduces costs and faults.

These developments point to a day when industries will function more effectively while upholding strict criteria of sustainability and excellence.

Benefits of Spectrum Laser Technology for the Environment

The use of spectrum laser technology is a breath of fresh air for companies throughout the globe, particularly in terms of environmental sustainability. Because of their reputation for accuracy and effectiveness, these lasers are used in production processes where waste is minimised. Businesses may reduce the amount of extra materials that wind up in landfills by using spectrum lasers.

Furthermore, these technologies use a great deal less energy than conventional techniques. This reduction lessens the carbon footprint associated with industrial operations in addition to lowering operating expenses.

Furthermore, spectrum lasers emit less particles when they cut or engrave. This move towards greener methods supports international efforts to mitigate climate change and improves air quality.

By using this technology, companies are moving towards more environmentally friendly practices in addition to improving their operating capacities. An increasing number of businesses are realising the value of environmentally friendly solutions, which is driving the shift towards sustainable production. At the front of this development is spectrum laser technology, which has the potential to completely change the way we approach production while protecting the future of our planet.